Published on

22/12/2011

7 Quality Tools Case Study – Scottish Courage

Use of the 7 Quality Tools in Red line Performance analysis

In this case study the Lean Group assisted a group comprising Team Leaders and manufacturing staff from the Tadcaster Bottling Plant of Scottish Courage to analyse the performance of one of the two recently commissioned bottling lines.

As a result of this exercise the team was able to accurately and factually identify the key priorities for improvement before preparing a plan for future improvement activities.

Objectives:

The Bottling Plant Manager set the broad goals of the team so that he could review their success at the end of the exercise.

The plant’s main focus is currently on improving the line efficiency.

Since much of the recent past has focused on equipment commissioning and introduction of new products it has left the line performance somewhat lacking.

The team was assigned to study the line running conditions for a complete shift, noting each breakdown that occurred, the action taken by the operator to restore running and what the true  cause was.

cause was.

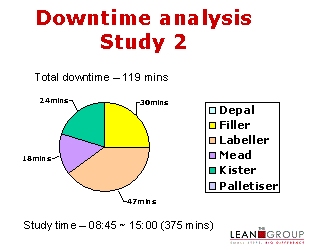

As a result of this exercise the team were able to identify that the largest amount of downtime occurred at the labeler machine.

Further analysis showed that the largest contributing element of the downtime was the misalignment of the label feed magazine – a crucial part that ensures the labels are fed to the applicator squarely. Investigation through fishbone analysis revealed two major causes:

Magazines damaged at location points and misfeed of magazine by the feed conveyor.

In the short term the team decided to ensure that the labeler operator was able to quickly attend to the stoppage. This was achieved through the redistribution of operator tasks.

In the short term the team decided to ensure that the labeler operator was able to quickly attend to the stoppage. This was achieved through the redistribution of operator tasks.

The team also agreed to carry out an overhaul of all magazines to ensure that all damaged units were identified and repaired.

As a result of the exercise the team were able to develop a targeted programme of improvement activities which they will be following during the course of the next 12 months.

Call us now on

01733 518100

Send us an enquiry

← Back to news list